Price consultation customer service

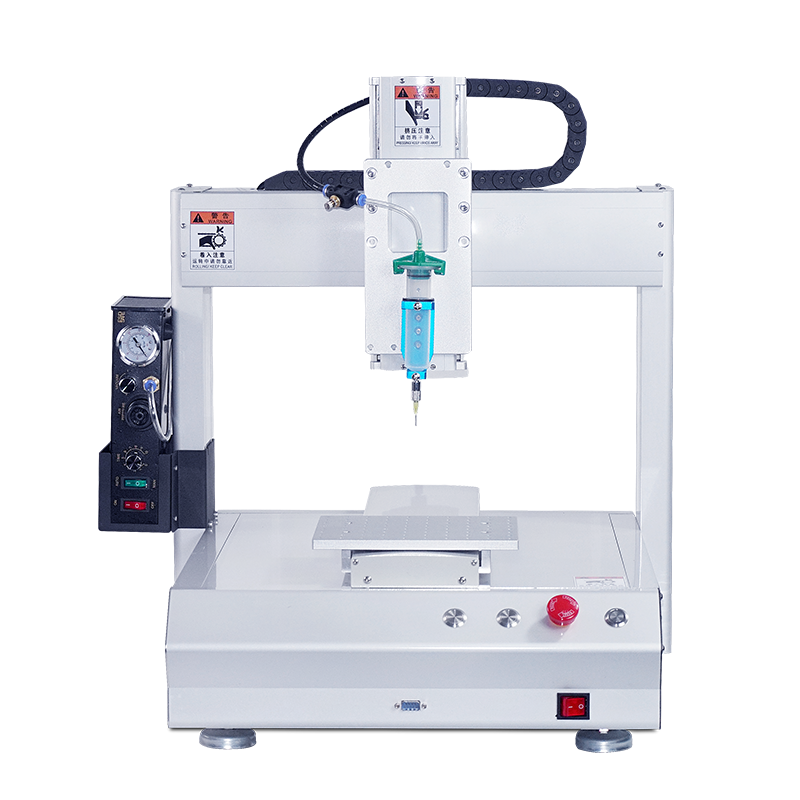

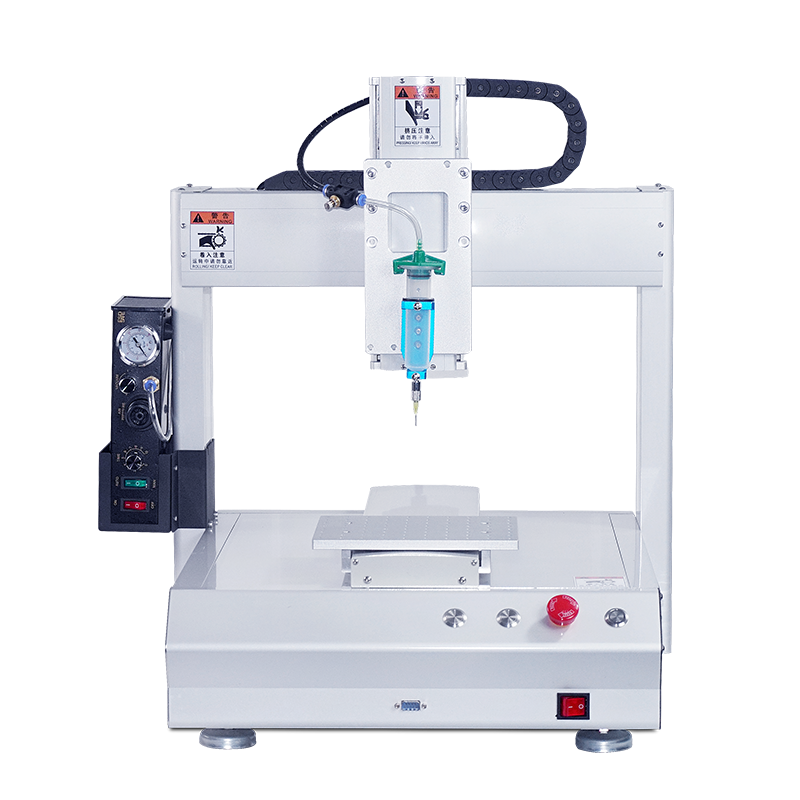

Equipment component description

Double Y-axis working platform

Dual platform alternating lock screw, lock screw while loading and unloading, equipment non-stop, higher efficiency

Blowing feed system

The feeder will directly blow the screws to the batch nozzle, saving the time to take the screws back and forth, efficient work

Alarm detection function

Imported electrical batch, 8-year control card special control system, with sliding teeth and floating lock detection and alarm function

Suitable for various products

Replace the feeder and nozzle, replace the fixture, you can switch products

This section describes the device brand configuration

Taiwan on silver rail

Italian Irate synchronous belt

Closed-loop servomotor

Aluminum profile die casting frame

Japanese Omron relay

Taiwan Mingwei power supply

Taiwan Qili speed electric batch

Red wave metal switch

Control card screw machine control system

Taiwan ADke electrical parts

Analysis of working principle of blowing screw machine

- The feeding machine arranges the screws in an orderly manner;

- The parting mechanism separates the screws to be locked;

- Automatically blow the screw to the clamp;

- The device is positioned above the screw hole to be locked.

- The batch head is pressed down, the electric batch is rotated, and the screws are locked;

- The above circular lock pay screws.

Air blown lock screw and product requirements

-

The general requirement is that the total length of the screw (diagonal length) should be more than 1.3 times larger than the diameter of the nut (special screw requirements depend on the specific size).

-

Product: After the screw is locked down, there is no obstacle in 1mm around the screw cap, and the screw head and the product will have plane contact, so enough space should be left.

Our equipment advantages:

-

Imported accessories, stable and durable: Closed loop servo motor, Taiwan Kili speed electrical lot, Taiwan silver guide rail, Taiwan TBI screw, Japan Omron Optoelectronics, Italy Italatai belt, Taiwan Ming Wei power supply, Ray driver, wave switch, Taiwan ADke electrical parts

Device action description:

First, manually put the product into the Y1 fixture, press the start button, automatically start to lock the product;

Second, manually put the new product into the Y2 fixture, press the start button, wait for the lock payment, Y1 product lock payment is completed, automatically start to lock the Y2 product;

Third, when the equipment locks the Y2 product, the Y1 product is taken out manually and put into the new product, waiting for the lock payment;

Fourth, the above cycle, the equipment around the cycle lock product, equipment non-stop high efficiency, manual need not wait.