Collections

-

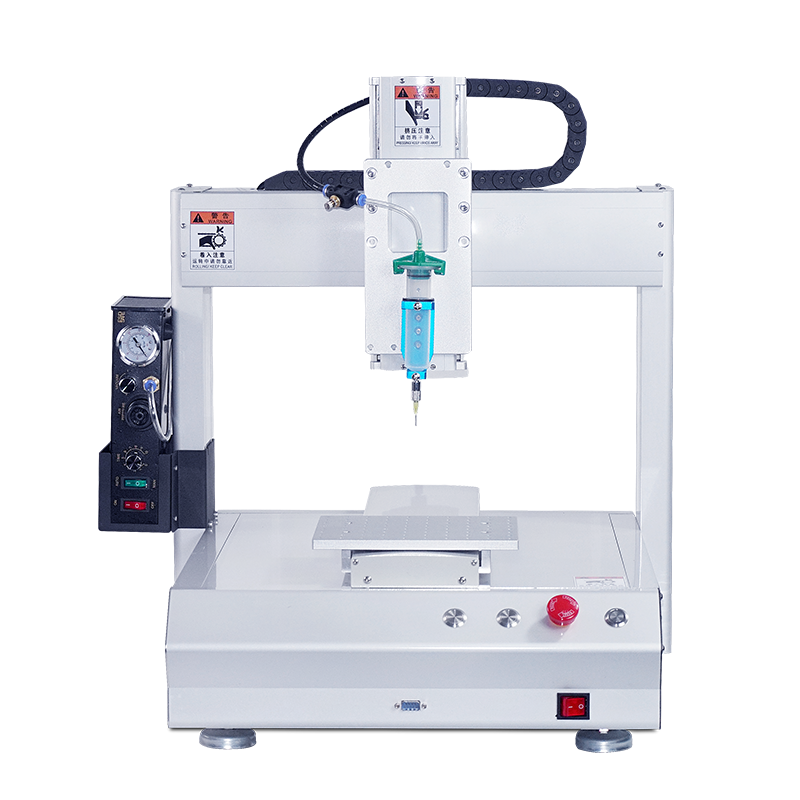

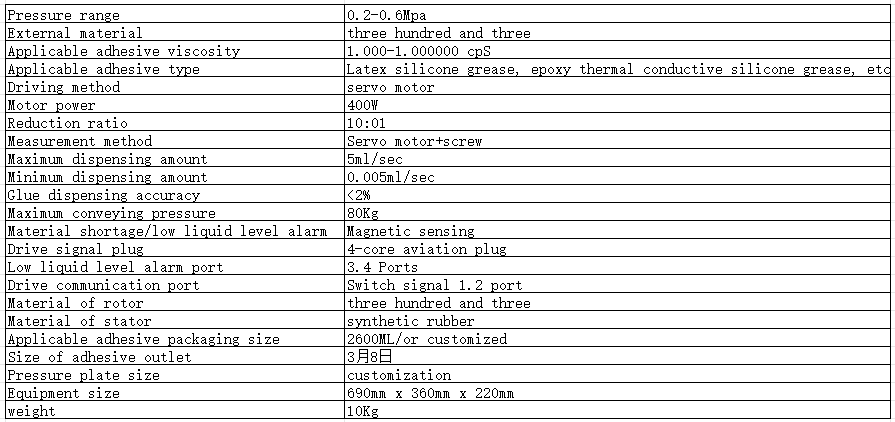

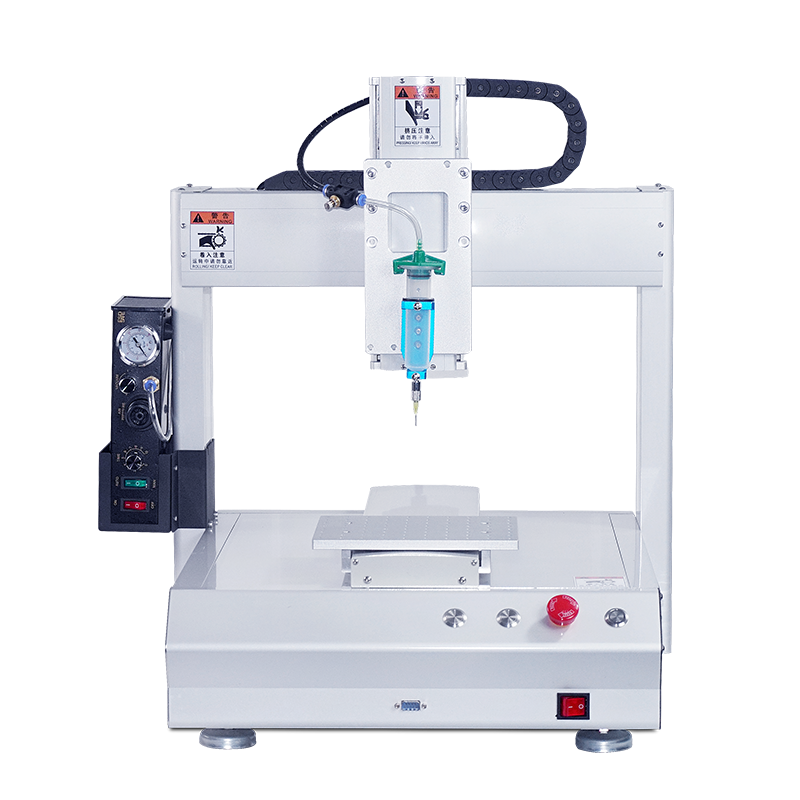

Automatic dispensing machine

Automatic dispensing machine is a kind of professional equipment instead of manual...

-

Screws tightening machine

Automatic screwdriver equipment to use a one-time all the screws to play....

-

soldering robot

Automatic soldering machine is a kind of automatic soldering equipment, which is...

-

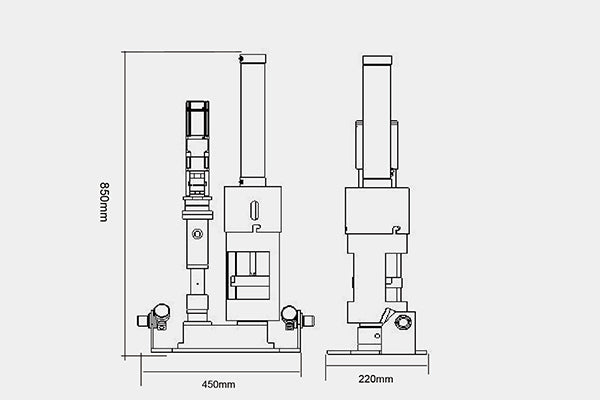

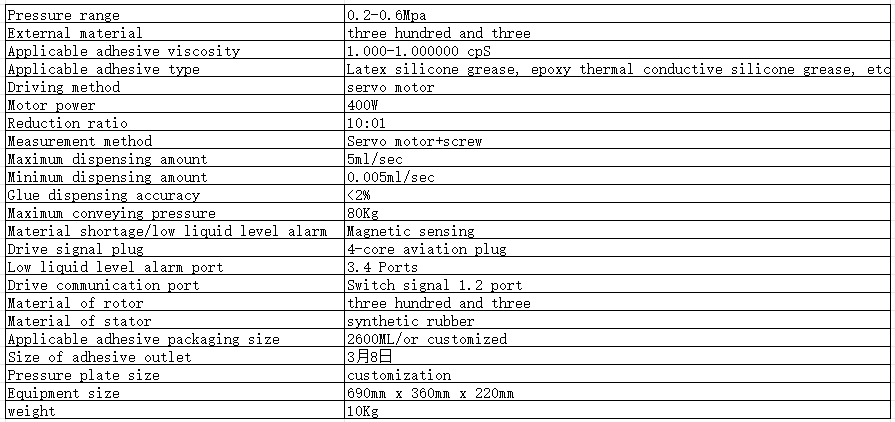

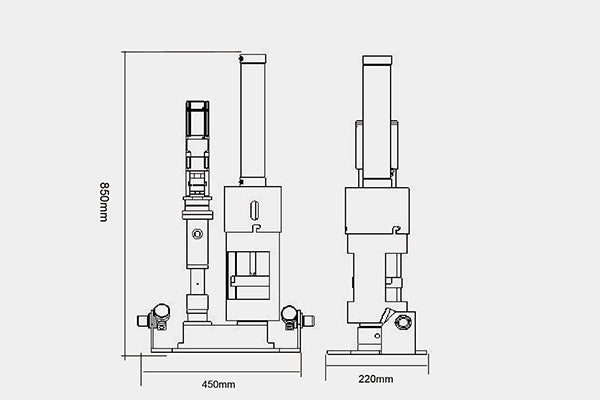

Automatic AB glue filling machine

Automatic Potting machine, AB Potting machine, epoxy Potting, PCB Potting,