Price consultation customer service

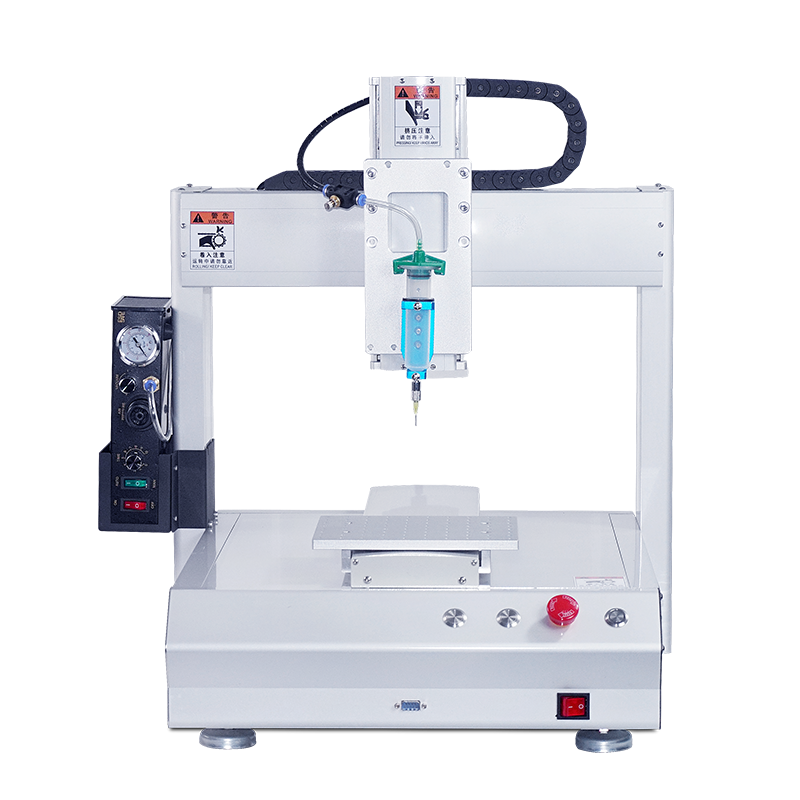

300CC twin barrel screw pump

Applicable to various medium and high viscosity fluids, such as silica gel, epoxy resin, grease, thermal conductive gel, thermal conductive silica gel, etc

The screw pump glue supply system uses cylinder pressure to deliver 300cc/330cc packaging glue barrels and screw pump self suction to push the material. The pressure is constant to maintain the material flow rate, and combined with precise time control of the switch valve, it ensures the dispensing volume and dispensing speed

Features and advantages

▲ Use 300ML/330ML and sausage glue packaging directly. Suitable for high viscosity adhesives with a viscosity of 10000-1000000.

Directly solve the problems of broken glue, unstable glue volume, and uneven lines caused by traditional pneumatic pressure pump pulses.

▲ Easy to operate, the device is equipped with a dedicated controller with a built-in touch screen. The low liquid level alarm switch can adjust the amount of glue through the working speed function of the controller.

▲ The dispensing accuracy can be controlled within ± 3%, with a minimum dispensing amount of 0.03g and a maximum dispensing amount of 5g/s,

▲ The overall design mechanism has a long lifespan, fewer types of replacement parts, and low replacement costs;

▲ Easy installation, compact structure, most suitable for automatic machine installation;

Technical parameters of feeding components

Dimensions: 400mm * 280mm * 1052mm

Power: 50W

Air pressure: 0.5~0.7Mpa

Cylinder thrust: 50KG (at 0.5Mpa air pressure)

Feeding method: cylinder push+pressure pump self-priming

Adhesive packaging: 2600cc packaging

Sealing material: PEEK/TEFLON/special rubber

Material of structural components: aluminum alloy anode/stainless steel

Applicable material viscosity:<1 million CPS

Applicable material hardness:<60HRC

Control mode: microcontroller control

Monitoring method: pressure sensor closed-loop control

Alarm prompt: shortage alarm, abnormal pressure alarm