Price consultation customer service

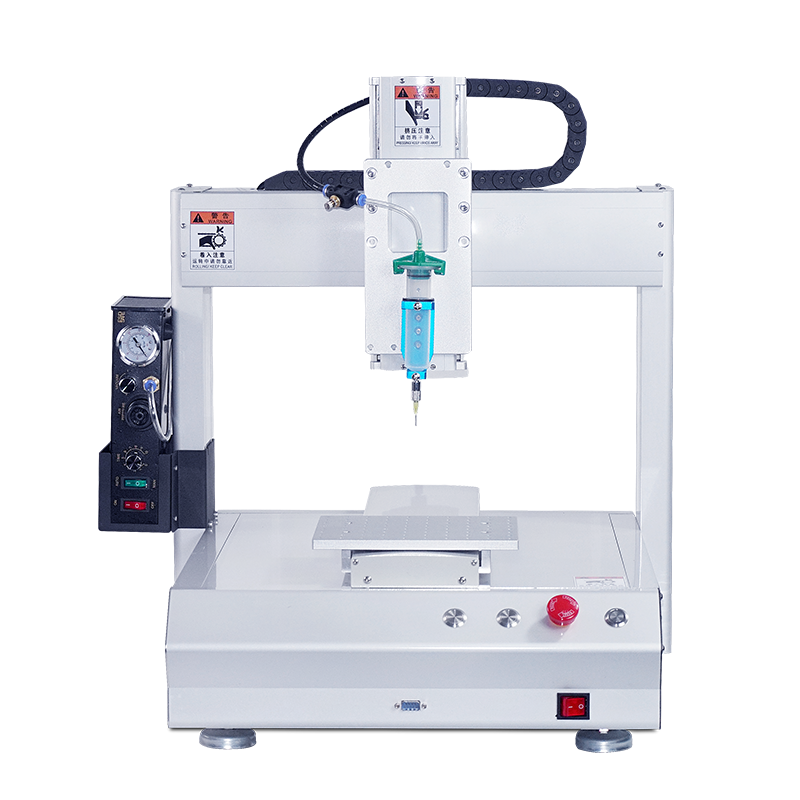

Double Y-axis operation + automatic blanking

Support to run two programming files at the same time, to achieve two products or two parts of a device screw lock

Feeder system

8 years of feeding machine experience, stable and durable, with digital display counting, digital display to adjust the vibration frequency function

Alarm detection function

Imported electrical batch, 8-year control card special control system, with sliding teeth and floating lock detection and alarm function

Wider scope of application

More ways to use. Support to run two programming files at the same time, you can lock different products, or different parts of the same product lock payment

This section describes the device brand configuration

- Taiwan silver rail

- Italian Iratai synchronous belt

- Closed-loop servo motor

- Aluminum mold casting frame

- Japanese Omron relay

- Taiwan Mingwei power supply

- Japan HIOS electrical approval

- Red wave metal switch

- Control card screw machine control system

- Taiwan Artak Electrical Parts

Our equipment advantages:

1, imported accessories, stable and durable: closed loop servo motor, Japan imported HIOS electrical batch, Taiwan silver guide rail, Taiwan TBI screw, Japan Omron Optoelectronics, Italy Italatai belt, Taiwan Ming Wei power supply, Ray driver, red wave switch, Taiwan ADke electrical parts;

2, motion control card + handheld box display control, 8 years of research and development experience, tens of thousands of sets of sales experience, three-axis linkage interpolation, fast running, easy to operate, easy to learn;

- Aluminum profile casting structure, solid, beautiful, high precision;

4,8 years of feeding machine, nozzle R & D, production and sales experience, stable and reliable;

Scope of application (double batch, double feeder, more combined functions)

1,large-size products, two electrical batches at the same time lock payment, can lock the same large-size products in different parts, the same size screws. Can also lock the same large size product in different parts, different sizes of screws.

2,One device to meet the needs of two devices, with different fixtures, you can lock two different screw products at the same time.

3,Lock a product, two Y axes alternately loading and unloading, alternating lock payment, higher efficiency.

| Model number |

Double platform adsorption automatic feeding lock screw machine |

| Electric screwdriver |

Taiwan Qili speed electric batch |

| feeder |

Independently developed |

| Control system |

Independent professional screw machine system |

| Mechanical platform travel range X/Y/Z(mm) |

500/300/300/100 |

| Maximum load |

1kg |

| Moving speed (mm/sec) |

0-800. |

| Lock pay a screw time |

About 0.8-1.5 seconds |

| repeatability |

± 0.02 mm/ Axis |

| Program recording mode |

Group 999 |

| Display mode |

7 "color screen |

| Motor system |

Closed-loop servomotor |

| rail |

Shangyin Taiwan |

| photoelectricity |

Japanese Omron |

| belt |

Italian Irate synchronous belt |

| Transmission mode |

Synchronization belt/lead screw |

| driver |

Ressay |

| Alarm function |

Floating locks, slipping teeth, missing locks |

| Applicable screw |

M1.2 - M6.0 |

| Input power supply |

Full voltage AC110V ~ 220V |

| External control interface |

RS232 |