Price consultation customer service

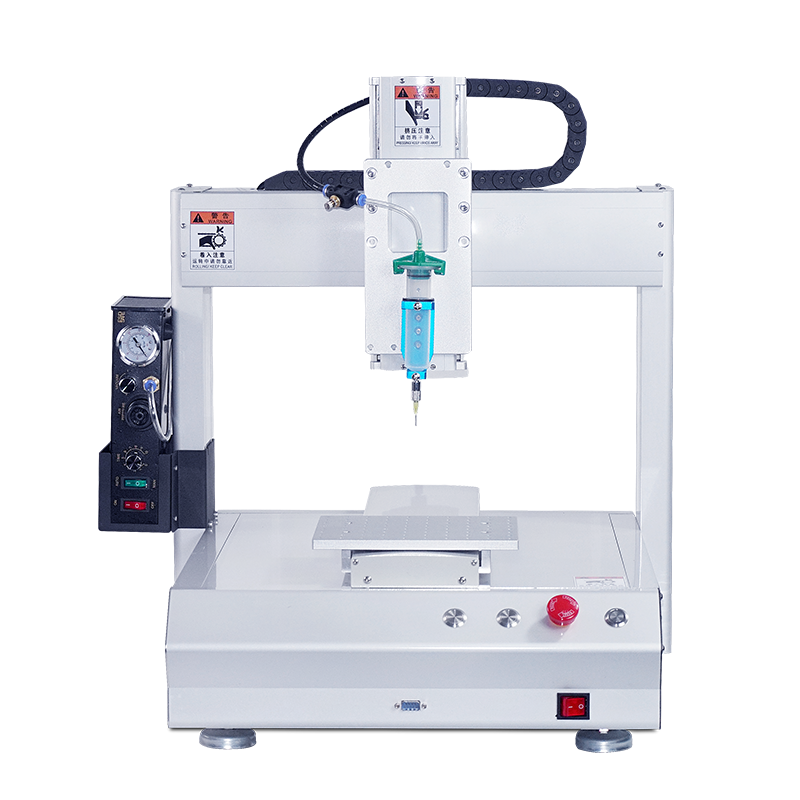

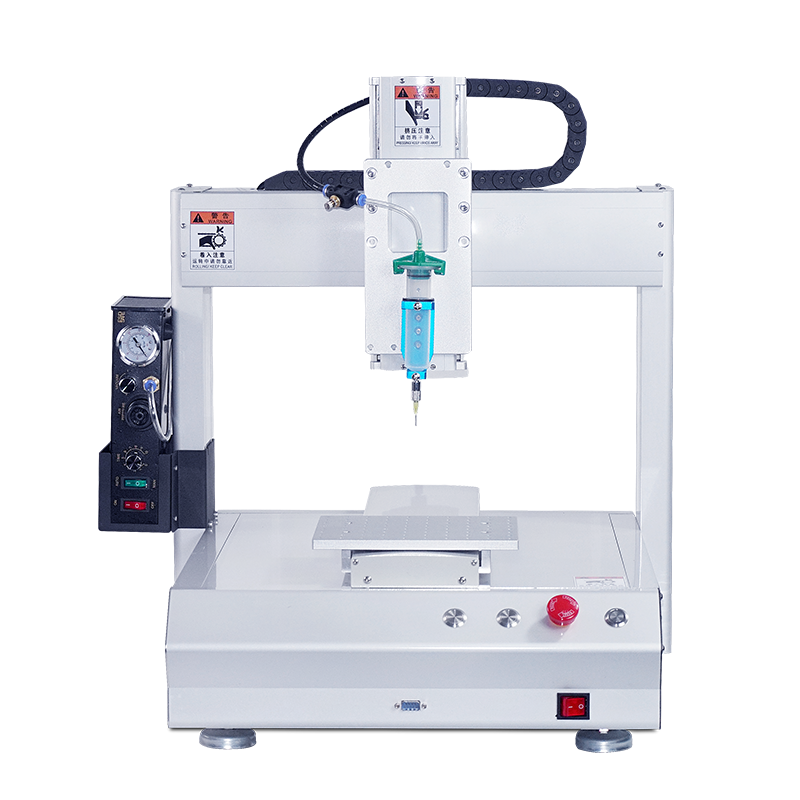

Equipment component description

Die casting aluminum profile platform

Independent opening mold, aluminum mold casting structure, strong machine, quality assurance, beautiful appearance

Fast and accurate dispensing

Less use of 2-3 workers, more accurate than manual, faster, save glue, just put the product can be dispense

Precision suction valve

Precision silicone suction valve, uniform dispensing, break the glue simply, no wire drawing

Suitable for various products

With 300 ml silicone barrel, easy to change glue. Replace the fixture and needle and use another product

This section describes the hardware configuration of the device brand

Taiwan on silver rail

Japan Shinano motor

Italian Irate synchronous belt

Taiwan Mingwei power supply

Japanese Omron relay

Red wave metal switch

Aluminum profile die casting frame

Dispensing machine control system

Equipment advantage

According to different needs, dispensing speed/dispensing amount/dispensing track (space point, line, arc, etc.) can be set separately.

Precision silicone suction valve, uniform glue, break the glue simply, no wire drawing, no glue drop.

300ml silicone barrel, easy to change glue, adjustable air pressure control glue amount.

High-end brand configuration: Japan Shino motor, Taiwan on silver rail, Japan Omron photoelectric switch, Italy Iratai belt, Lei Sai drive, Taiwan Ming Wei power supply, red wave switch.

Independent mold opening, aluminum mold casting structure, solid, beautiful, high precision, quality assurance, beautiful appearance.

Handheld teaching programmer, support English and Chinese dual interface, easy to learn, 8 years of development experience, tens of thousands of sets of application cases. We have a special guide to use, only 30 minutes to master the basic.

The system can store hundreds of processing files, each file can support 8000 instructions, can be called out when used, support DXF and PLT file import, automatic path optimization function.

Monthly sales of 500 units of equipment, rich on-site practical use cases and experience, 30 people of after-sales service and process commissioning team, to ensure after-sales service and technical support.

One year free warranty, lifetime free maintenance.

| Model number |

Three axis silicone automatic dispensing machine |

| Dispensing range X/Y/Z(mm) |

300/300/100 |

| Programming mode |

Teach programming or graphic import |

| Movable graphic trajectory |

Point, line, arc, circle, curve, multi-segment line, helix, ellipse |

| Dispensing valve |

Precision suction dispensing valve |

| Glue dispenser |

300 ml silicone barrel |

| Motor system |

Japan Shinano motor |

| Minimum discharge |

0.01 ml |

| Glue production frequency |

5 times per second |

| Maximum load |

10kg |

| Moving speed (mm/sec) |

0-500 |

| repeatability |

± 0.02mm |

| Control mode |

Motion control card + handheld box |

| Number of program records |

100 groups |

| Display mode |

LCD teaching box |

| driver |

Ressay |

| rail |

Shangyin Taiwan |

| Photoelectric switch |

Japanese Omron |

| Transmission mode |

Italian Irata belt |

| Input power supply |

Full voltage AC110V ~ 220V |

| External control interface |

RS232 |