Price consultation customer service

Introduction to piezoelectric valves:

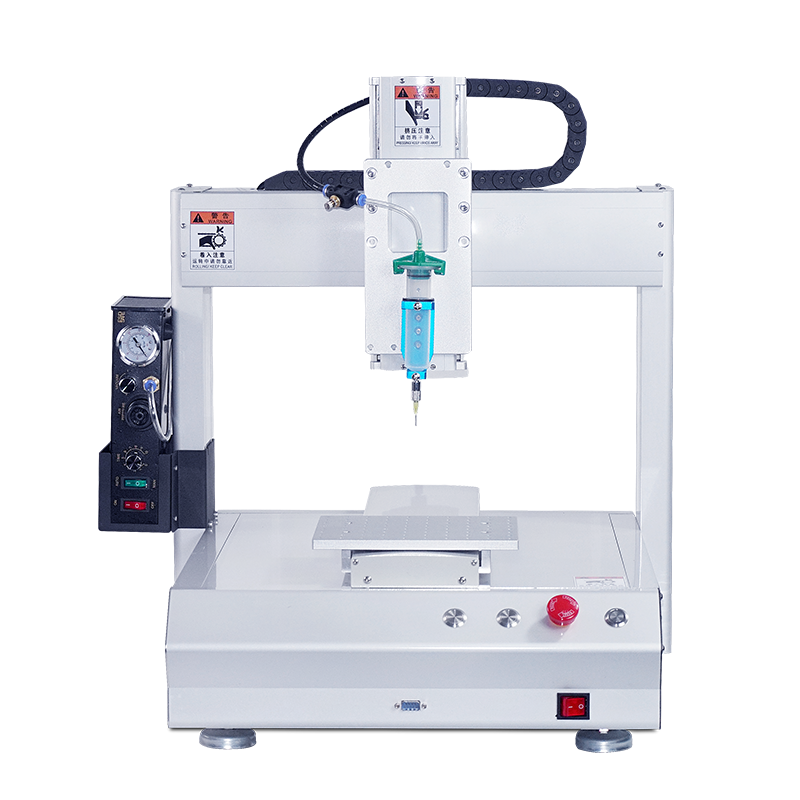

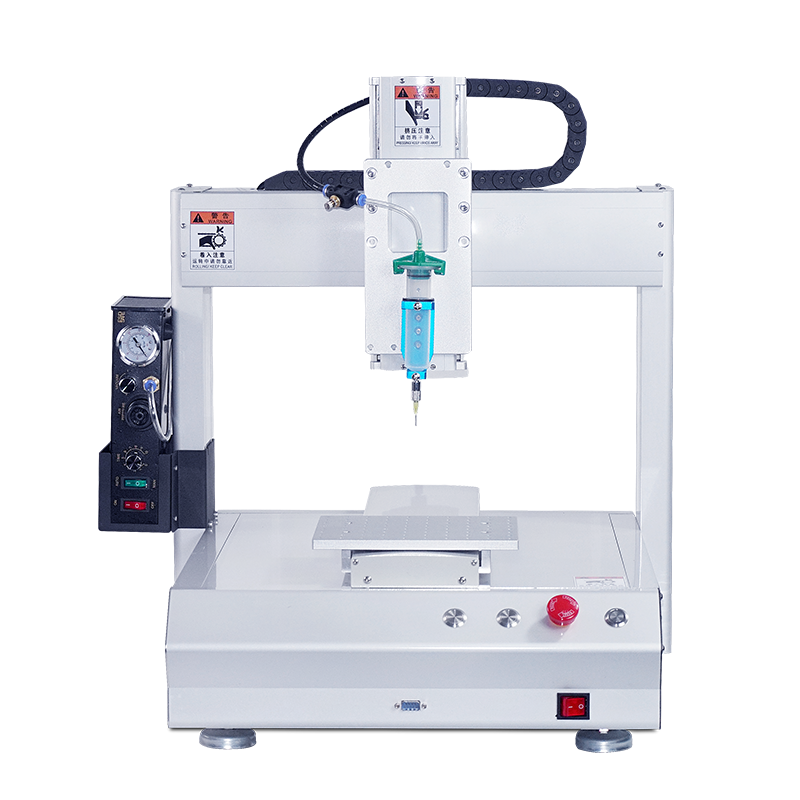

Micro Dispensing System - XH 1000 Series ceramic material is used as the driving

force,Move the firing pin up and down quickly,

Achieve high speed spraying of glue,Because the piezoelectric ceramic material reaction

speed is fast,High precision and excellent stability,Compared to pneumatic injection

valves driven by compressed air,Eliminate instability caused by fluctuations in air source

pressure,The stability of piezoelectric ceramic injection valve is obvious,

The valve body is especially suitable for PCB board packaging, 3C electronic

product production, LED photoelectric industry,FPC flexible circuit board

production, trace paint ink filling,Biological or medical reagent verification, etc.

Product features:

High speed:Precision piezoelectric driver, fast dispensing frequency,

limit up to 1500Hz per second.。

Quick debugging:The modular design simplifies Tappets debugging and

enables fast calibration at the top.

High efficiency:non-contact dispensing eliminates Z-axis movement and

effectively improves production efficiency

Long life:Replaceable superhard alloy nozzles withTappets,Longer service life.

microscale:As small as 0.5nl glue, line width 0.25mm, point diameter 0.2mm.

Uniformity:Set a constant temperature heating module, high-speed injection

valve dispensing consistency can reach ±2%.

Simple maintenance:integrated runner design, minimal spare parts, can be

quickly disassembled, accuracy unchanged.

Low cost:patented design structure, maintenance only needs a small amount of consumables, saving maintenance costs in the production process.

Stability:piezoelectric valve Tappets stroke is small, the injection force is large, can effectively prevent the phenomenon of bubbles and scattered points.

Piezoelectric valve specification:

Dispensing method: Non-contact dispensing mode

Suitable for liquid types : Bottom filling glue, UV glue, epoxy glue, silica gel, red glue, etc

Applicable liquid viscosity : 0 - 200000 cps

Operating frequency : Max: 1200 Hz

Applicable nozzle type : Integrated nozzle: 0.05-0.3mm

Glue supply pressure : Glue pressure: 0.01-0.2Mpa

Valve body mass : 500g

Overall dimension : L53mm*W90mm*H110mm

Controller specification:

Control mode : Electronic analog circuit

Dispensing time control : Digital circuits/parameterization

Power supply/Power : AC220V/50Hz*120W

Controller quality : 2kg

Overall dimension : L203mm*W120mm*H135mm